Engine Camshaft Manufacturers: A Comprehensive Guide

Introduction

Welcome to client-diesel.com, your ultimate resource for all things related to the automotive industry. In this comprehensive guide, we will delve into the intricate world of engine camshaft manufacturers. Whether you're an auto enthusiast or a professional in the field, this article will provide you with valuable insights into the manufacturing process, quality standards, and latest innovations in engine camshaft production.

Understanding Automotive and Auto Parts Manufacturing

Before diving into the specifics of engine camshaft manufacturers, let's first explore the broader realm of automotive manufacturing. This industry encompasses a wide range of processes, from designing and engineering to production and distribution of vehicles and their components. One crucial aspect of this intricate ecosystem is the manufacturing of auto parts and supplies, such as engine camshafts.

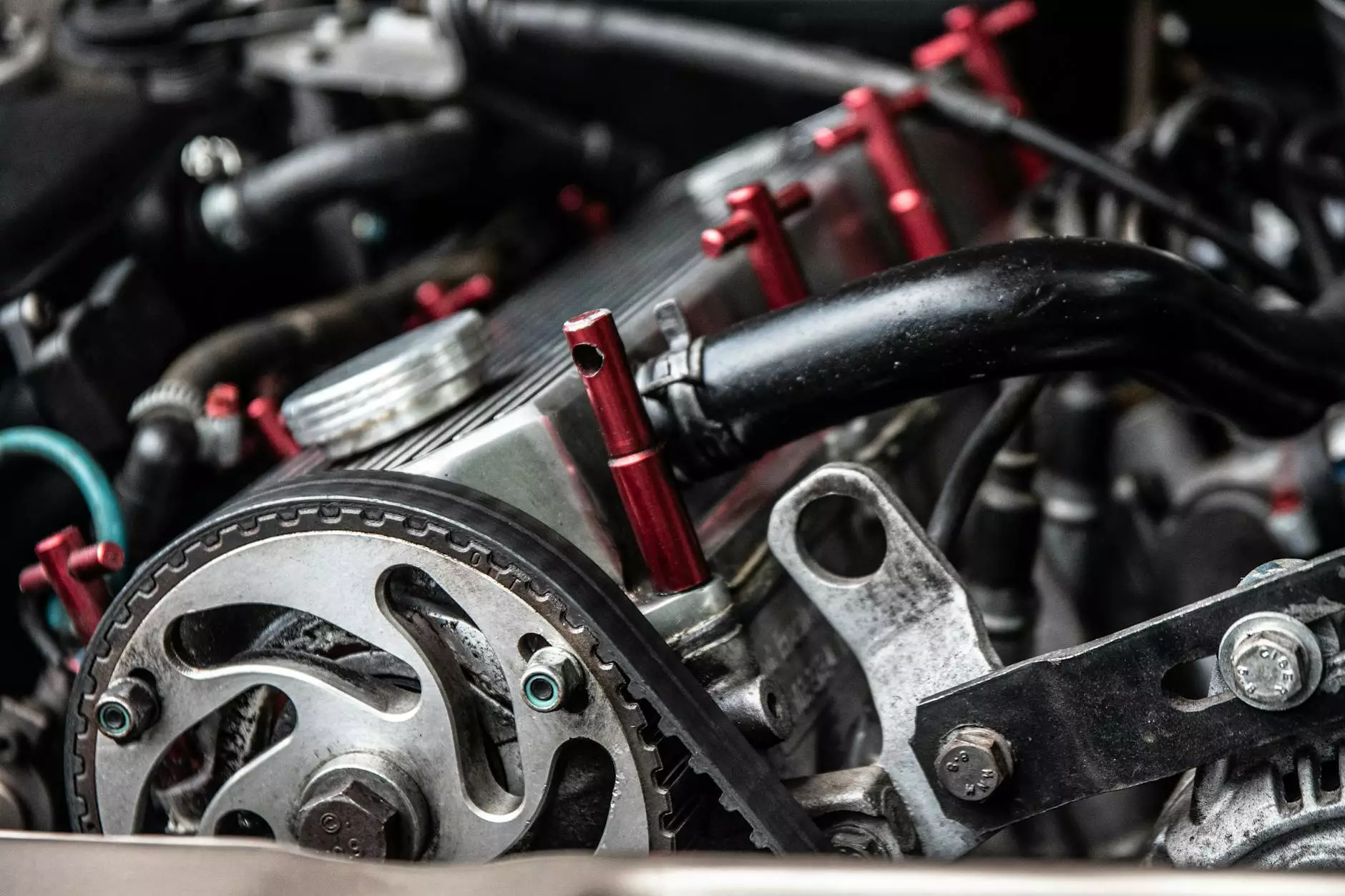

The Importance of Engine Camshafts

An engine camshaft plays a vital role in the proper functioning of an internal combustion engine. It controls the opening and closing of the engine's valves, allowing for the intake of air and fuel while expelling exhaust gases. Engine camshafts need to be precisely engineered to ensure optimal performance, efficiency, and durability.

Key Factors for Engine Camshaft Manufacturers

When it comes to choosing the right engine camshaft manufacturer, several key factors must be considered. Let's explore each factor in detail:

Quality Standards and Certifications

A reliable engine camshaft manufacturer adheres to stringent quality standards and holds relevant certifications. These certifications, such as ISO 9001, ensure that the manufacturing process meets rigorous criteria and guarantees consistent quality and reliability.

Research and Development

Top-notch engine camshaft manufacturers invest heavily in research and development. By keeping up with the latest technological advancements and industry trends, they can innovate and produce camshafts that meet the ever-evolving demands of modern engines. This commitment to R&D ensures that customers receive high-performance and efficient camshafts.

Material Selection

The choice of materials is critical in engine camshaft production. Manufacturers must carefully select materials that offer excellent strength, durability, and heat resistance. Steel alloys, such as carbon steel or alloy steel, are commonly used due to their favorable mechanical properties.

Precision Manufacturing Techniques

Engine camshafts require precise manufacturing techniques to guarantee optimal performance. Processes such as computerized numerical control (CNC) machining and grinding help achieve the desired camshaft profiles, ensuring precise valve timing and duration for optimal engine efficiency.

Quality Control and Testing

A reputable engine camshaft manufacturer conducts rigorous quality control and testing throughout the production process. From raw material inspections to final product checks, every step is monitored to ensure conformity to specifications. Advanced testing methods, like non-destructive testing and surface analysis, ensure that the camshafts meet strict quality standards.

Leading Engine Camshaft Manufacturers

Manufacturer A: Innovating the Future of Camshaft Production

Manufacturer A is a prominent engine camshaft manufacturer known for its relentless pursuit of innovation. With a keen focus on research and development, they consistently introduce cutting-edge technologies and designs to produce camshafts that push the boundaries of performance and efficiency. Their commitment to quality and precision is evident in every camshaft they produce.

Manufacturer B: Setting the Industry Standard for Quality

Manufacturer B stands out in the automotive industry for its unwavering emphasis on quality standards. With internationally recognized certifications, they maintain strict manufacturing processes to ensure that their camshafts meet or exceed customer expectations. Their extensive quality control and testing procedures guarantee the reliability and durability of their products.

Manufacturer C: Excellence in Craftsmanship and Durability

Manufacturer C takes pride in its craftsmanship, producing engine camshafts that embody precision and durability. With skilled engineers and technicians, they employ state-of-the-art manufacturing techniques to create camshafts that withstand the demands of high-performance engines. Their commitment to customer satisfaction has earned them a reputation for excellence in the industry.

Conclusion

As we conclude this comprehensive guide on engine camshaft manufacturers, it is evident that choosing the right manufacturer is essential for optimal engine performance. Manufacturers like A, B, and C exemplify excellence in the automotive industry, consistently delivering camshafts that meet the highest quality standards. From stringent quality control to cutting-edge technologies, these manufacturers are at the forefront of innovation and precision. Remember to consider factors such as quality standards, research and development, material selection, precision manufacturing techniques, and extensive testing when selecting an engine camshaft manufacturer. With client-diesel.com as your trusted resource, you can stay informed and make informed decisions for all your automotive needs.